Glove Boxes

Isolation Glove Boxes

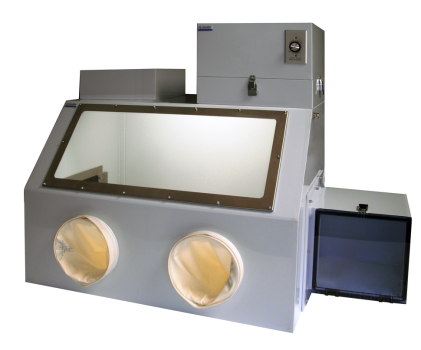

2100 Series – Standard Glove Box

The 2100 Series isolated chamber gloveboxes are designed to provide a positive pressure environment to manipulate objects in a controlled atmosphere. We offer a single, three feet, model with two glove ports and a twin, five feet, model with four glove ports. They are available in cleanroom-compatible materials such as clear acrylic, static-dissipative PVC and polypropylene and a wide variety of accessories. When used in conjunction with nitrogen, argon or an inert gas, sensitive substances, and components can be manipulated in a very high purity inert atmospheres.

Our 2100 Series gloveboxes are an ideal choice for basic laboratory applications and general processing.

2200 Series – Portable Glove Box

The 2200 Series gloveboxes offer a lightweight and portable option for handling samples in a controlled environment. They serve a similar function as the 2100 series isolated gloveboxes but provide a compact and affordable form factor in a wide range of materials and accessories for humidity and oxygen control & monitoring.

2200 Series gloveboxes are ideal for a variety of manufacturing and testing procedures and off-site applications.

2500 Series – Compact Glove Box

The 2500 Series compact gloveboxes are designed to be ultra-portable and lightweight so that they can be set up anywhere. The glove ports are located on the sides to allow for a compact size. It features a large front tilt-up access door for easy transfer of samples and substances. By adding the gas ports, an inert gas such as nitrogen, argon can be used to control the oxygen and humidity level. 2500 series gloveboxes are available in cleanroom-safe materials including clear acrylic, static-dissipative PVC and polycarbonate.

2700 Series – Vacuum Glove Box

Cleatech’s 2700 Series Vacuum Glove Box is designed for anaerobic processing in a dry inert gas environment. Constructed from 1″ Acrylic material, features include two removable glove covers, fully removable top, two vacuum valves with a barbed fitting for vacuum and nitrogen backfill, vacuum gauge to monitor the main chamber and airlock internal pressure.

2710 Series – Vacuum Glove Box Stainless Steel

Cleatech’s 2710 Series Stainless Steel Vacuum Glove Box has been designed to handle down to 29.9″ of Hg (0.1 Bar), which can be filled with a high purity inert gas to be filtered out the active substances circularly. Made entirely from 11 gauge stainless steel (3mm thick) with a reinforced frame strong enough to handle 29.9″ of Hg with great corrosion resistance.

2800 Series – Stainless Steel Isolation Glove Box

Designed to remove oxygen and humidity providing a clean and controlled atmosphere environment. Constructed from 304-grade stainless steel continuous-steam welds. Stainless steel is able to resist a wide range of chemicals, moisture, and heat. Easy to decontaminate and clean. This box is ESD-safe, perfect for electrostatic-sensitive applications.

Ideal for semiconductor, pharmaceutical manufacturing, research, and testing applications.

Filtered Containment Glove Boxes

2300 Series – Powder Containment Glove Box

The 2300 Series open exhaust loop gloveboxes can be factory configured as a negative or positive pressure system. A negative pressure system is designed to protect operators and environment against contamination. They are ideal for lab operations such as pharmaceutical powder packaging where particle contaminants are generated. Incoming air is passed through HEPA or ULPA filters to remove particles. An additional HEPA, ULPA or activated carbon filter can be added to remove contaminants and fumes from the exhaust air.

Positive pressure filtration gloveboxes are designed to protect samples against airborne particles. Samples are protected by filtering captured room air through a HEPA or ULPA filter before entering the chamber and returning the air back to the room through optional HEPA filter.

2400 Series – Air Recirculating Containment Glove Box

The 2400 Series simple closed-loop glovebox provides a clean processing environment by continuous recirculating filtered air through HEPA or ULPA filters. Particulates and contaminants generated by the internal application are removed from the flow of air. Additional, any inert gas such as nitrogen or argon can be used to control internal humidity and oxygen levels.

The multi-configuration models can be modified from a closed-loop isolation environment to an open-loop containment chamber by opening the valves. The valves also let you set the percentage of fresh air entering the chamber.

2600 Series – Laminar Flow Glove Box Isolator

Positive Pressure Laminar Air Flow Glove Box Isolators are designed to provide a sterile positive pressure environment for the compounding of non-hazardous drugs. HEPA filtered unidirectional air flow supply within both the work zone and antechamber areas to assure ISO Class 5 conditions and sterility and minimizing cross contamination.

Anaerobic Processing Chambers

BACTRON anaerobic chambers by ShelLab provide glove-free handling of samples with a consistent, oxygen-free, environment that promotes faster sample turnaround. Modular equipment within the chamber facilitates the completion of basic workflow procedures from unpacking of materials to inoculation, incubation, inspection, and recovery.

Glove Box Systems

Cleatech LLC is the leading manufacturer of humidity controlled and static charge safe cabinets chambers in Orange County, California. Serving the scientific industry with top quality products at competitive prices. Our products meet the requirements for the semiconductor, biopharmaceutical and medical device industries. Give us a call at (888) 216-8033 to request a quote.

Glove Box Features

Glove Box Standard Features

- Gloveboxes are available in Acrylic, Static-Dissipative Acrylic, Static-Dissipative PVC, Non-Dissipative PVC and Polypropylene

- Internal access doors open inward to allow for easy parts transfer into the glovebox.

- All doors use stainless steel frames that increase the structural rigidity of the door and feature q one-piece rubber bulb, vinyl gasket.

- Pass-through transfer chamber minimizes nitrogen loss and contamination inflow while parts are placed or removed. The airlock includes an optional 1/4″ NPT Push-to-Connect Gas-in port and an automatic pressure relief valve.

- Removable, fully-gasketed, back wall for operations involving large equipment

Standard Options for Containment Glove Boxes

- Blower module features a backward curved adjustable speed impeller 510-CFM, permanently lubricated, automatic reset thermal overload protection, UL Listed; CSA Certified in a Polypropylene Housing.

- Primary (S-2300 models only) HEPA Filter 99.97% efficient at trapping particles as small as 0.3 microns. Filter media is ultrafine glass fiber, Maximum temperature is 180° with 5 7/8″ thick meet UL Class 2 flame retardancy requirements.

- Exhaust HEPA Filter 99.97% efficient at 0.3 microns or ULPA 99.999% efficient at 0.12 microns with 3″ thick removes contaminants from the exhaust gas to make it safe for indoor release

- Power Strip 110VAC/60Hz

- Stainless Steel work surface prevents scratching.

Standard Options for Isolation Glove Boxes

- Automatic Purge Control Unit accurately controls the relative humidity and provides a variable nitrogen purge into the glovebox. The purge control units provides a continuous low flow purge during normal operation in order to maintain a positive pressure that blocks out contaminants. When humidity levels rise above an adjustable set point, it switches to a higher flow purge to quickly block out entering moisture and contaminants.

- Humidity Control Unit provides automatic low-humidity control capable of measuring and displaying humidities inside the glovebox in the range 5-100%RH. It accurately controls preset relative humidity (+/- 2% RH) and purges nitrogen when the moisture climbs above an adjustable set point.

- Automatic pressure relief valve provides safe pressure relief

- Power Strip 110VAC/60Hz

- Stainless Steel work surface prevents scratching.

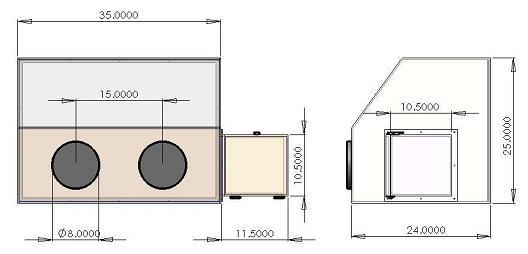

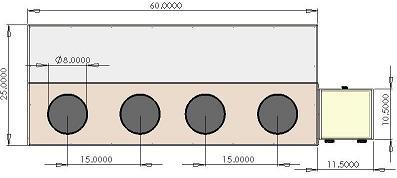

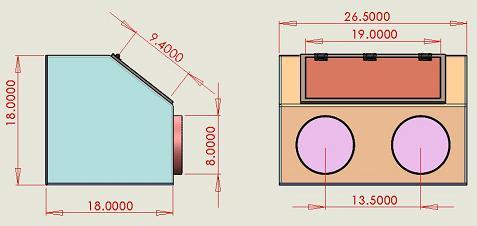

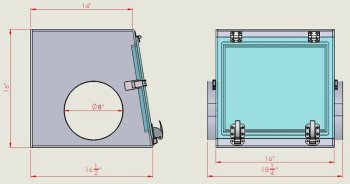

Glove Box Dimensions

Cleatech gloveboxes are available in Acrylic, Static-Dissipative Acrylic, Static-Dissipative PVC, Non-Dissipative PVC and Polypropylene with two or four glove port. Below you can see the dimensions of the standard two-port & four-port gloveboxes.

Our Clients